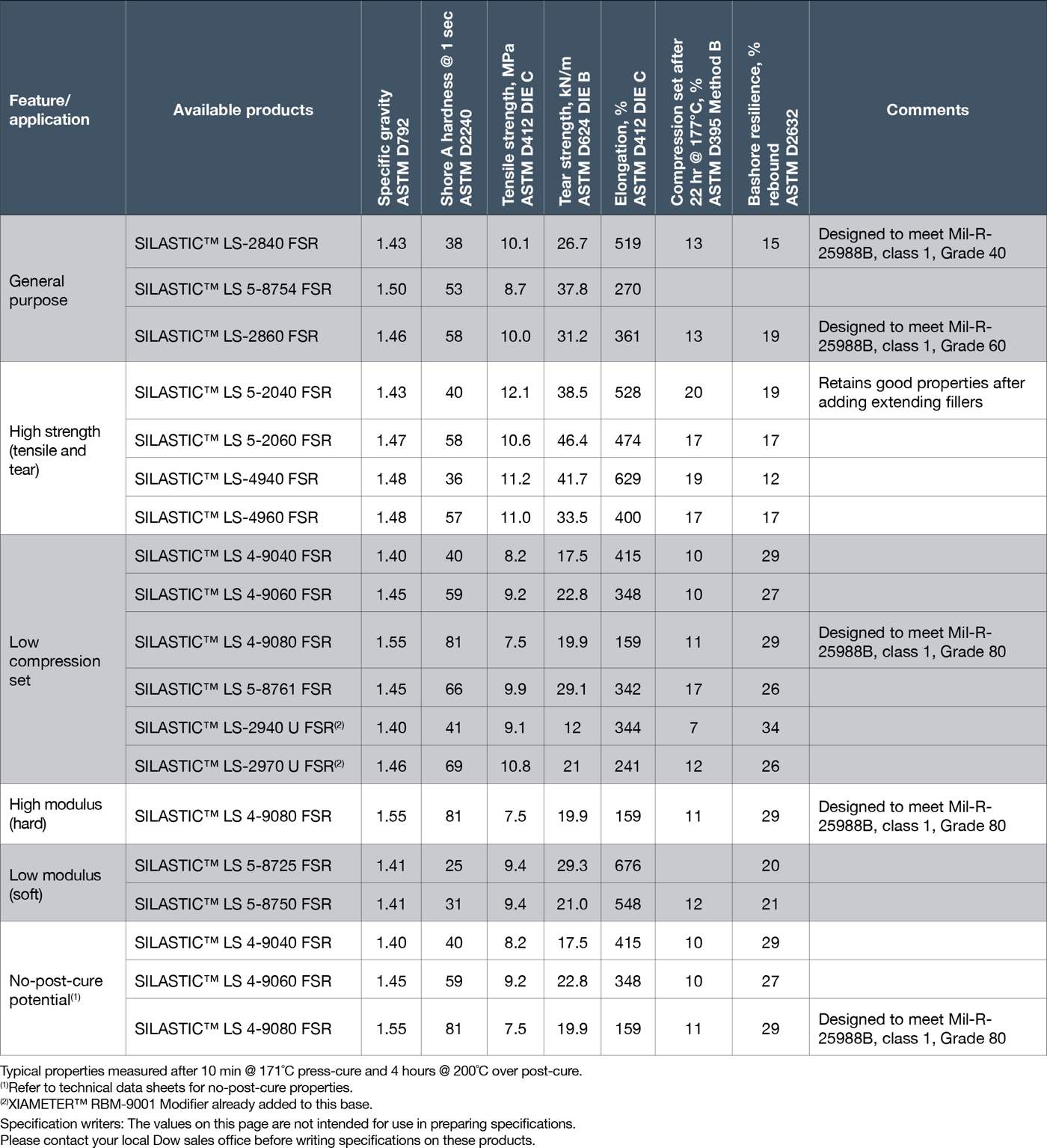

SILASTICTM Fluorosilicone Rubber (FSR) Bases are high-consistency, uncatalyzed materials that can accept commercially available curing agents (catalysts), performance additives/modifiers, and coloring pigments. Various FSR bases can be blended together to achieve desired values for selected performance and/or processing properties. These FSR bases:

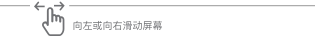

• Maintain excellent mechanical properties over a wide temperature range • Offer excellent resistance to fuels, oils, solvents and aggressive fluids

• Easily pigmented; supplied as off-white or translucent materials

SILASTICTM Fluorosilicone Rubber (FSR) Compounds are ready-to-use, heat-curable blends of high-consistency fluorosilicone rubber bases, fillers, modifiers, vulcanizing agents and coloring pigments.

Typical performance features of SILASTICTM FSR Compounds are:

• Exceptional extreme-temperature (hot and cold) performance

• Excellent resistance to fuels, oils, solvents and aggressive fluids

• Acid-gas resistance

• Good balance of tensile, elongation and tear resistance

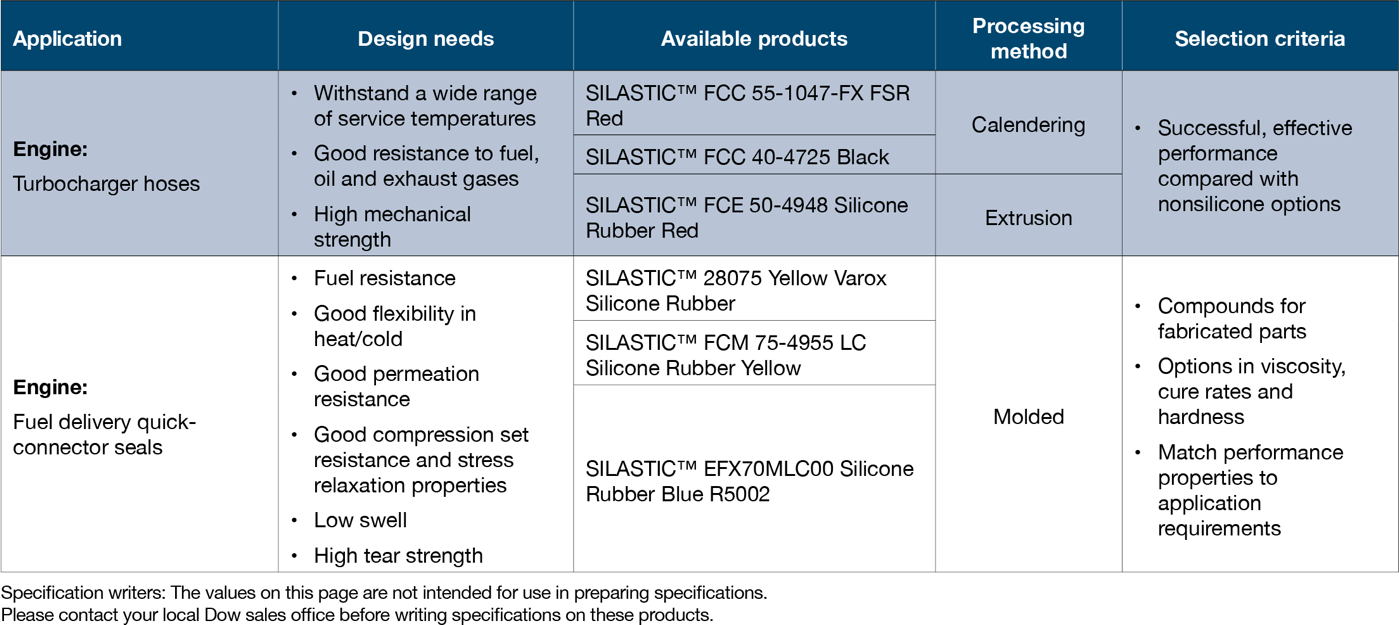

SILASTICTM FSR Compounds offer versatile processability, enabling design efficiency and flexibility. They can be extruded, calendered or molded, making the materials easy for fabricators to work with.

• Extruding: Products such as tubing and profiles can be extruded easily.

• Calendering: Fluorosilicone rubber can be calendered into long, thin sheets of uniform thickness, either unsupported or fabric-reinforced. This makes them ideal for flat seals and bands.

• Molding: Parts can be produced in a variety of shapes and sizes by compression, transfer or injection molding.

SILASTICTM FSR Compounds can help you meet goals related to:

• Climate change, with options suitable for turbocharger hoses and battery electric vehicles.

• Waste and pollution, as FSR is a fantastic sealing option. It is durable and long-lasting. FSR supports process containment and reduction of hazardous chemical leaks.